An In-Depth Analysis of Metal Additive Manufacturing

This interactive report translates a comprehensive analysis of metal 3D printing into an explorable experience. Navigate through core technologies, industrial applications, economic factors, and the future of manufacturing in space.

Core Technology Comparator

Metal AM is not one single process. Select a technology below to explore its fundamental principles, advantages, and limitations. This allows for a direct comparison of the trade-offs between speed, resolution, and material properties.

Industrial Applications Explorer

Adoption of metal AM is driven by the unique economic and performance priorities of each industry. Click on a sector to discover its key drivers, primary applications, and landmark case studies.

Aerospace & Defense

Driven by performance-per-kilogram, focusing on lightweighting, part consolidation, and thermal management.

Automotive

Driven by cost-per-part, focusing on rapid prototyping, custom tooling, and high-performance niche vehicles.

Medical & Dental

Driven by patient-specific efficacy, enabling mass customization of implants and surgical guides.

Economic Dashboard

Explore the financial landscape of metal AM, from raw material costs to the critical break-even analysis against traditional manufacturing methods like molding.

Cost Per Part: 3D Printing vs. Molding

This chart illustrates the fundamental economic trade-off. 3D printing has no tooling cost, making it ideal for low volumes. Molding (MIM) has high upfront tooling costs, but becomes far cheaper per part at high volumes. The "break-even point" is where the lines cross.

Metal Powder Costs (USD per kg)

System Acquisition Costs (CapEx)

Accessible Systems

$100,000 - $200,000

Industrial Production Systems

$500,000 - $1,000,000+

11-25%

Projected Market CAGR

~45%

Market Share of Top 3 Vendors

The Aerospace Frontier

Aerospace is the ultimate proving ground for metal AM. This section highlights a recent success in rocket manufacturing and details the profound challenges of printing in the harsh environment of space.

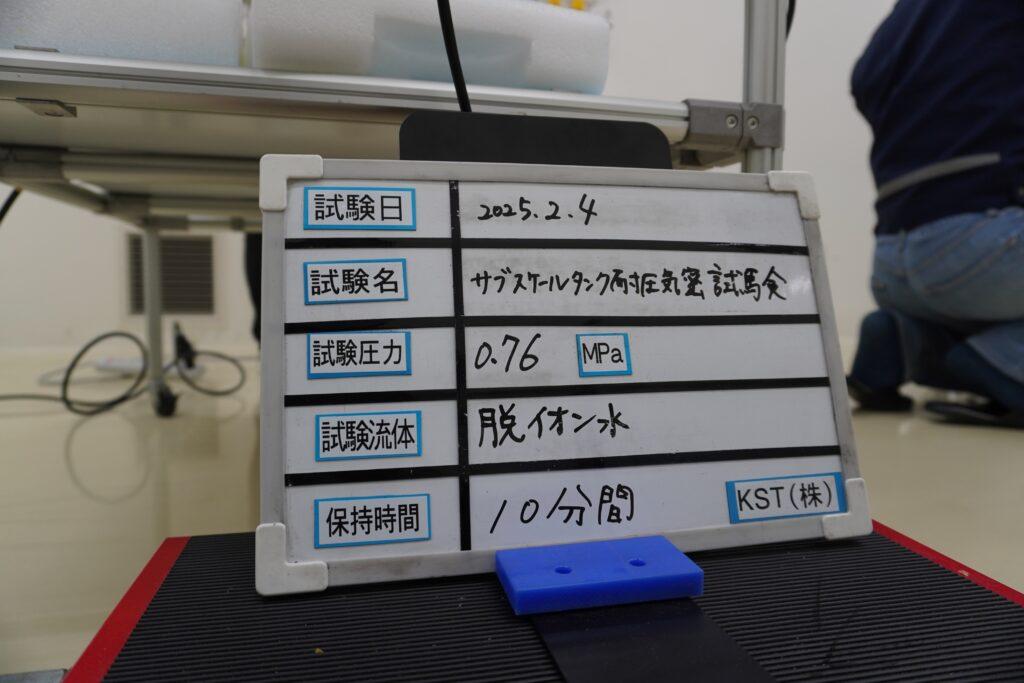

Case Study: Japan's 3D-Printed Rocket Tank

In March 2025, ISC successfully tested Japan's largest 3D-printed propellant tank using WAAM, validating the technology for agile development of critical space hardware.

Refer

- ✓Timeline: Design to testing completed in under 1 year.

- ✓Pressure Test: Withstood 0.76 MPa, meeting targets.

- ✓Significance: Proved WAAM can produce large, structurally sound pressure vessels for spaceflight.

Grand Challenges of In-Space Manufacturing

Printing in space is not as simple as launching a terrestrial printer. The entire process must be re-engineered to overcome fundamental physics challenges.

- Microgravity: Surface tension dominates, causing molten metal to "ball up" instead of spreading evenly.

- Vacuum: Creates a pure environment but causes material outgassing, which can contaminate sensitive equipment.

- Radiation: High-energy particles can degrade material properties and alter crystalline structures over time.

- Residual Stress: Locked-in stresses from printing can lower fatigue life and lead to premature failure under launch vibrations.

- Qualification: Parts require extremely rigorous testing to prove the process is repeatable and reliable for mission-critical use.